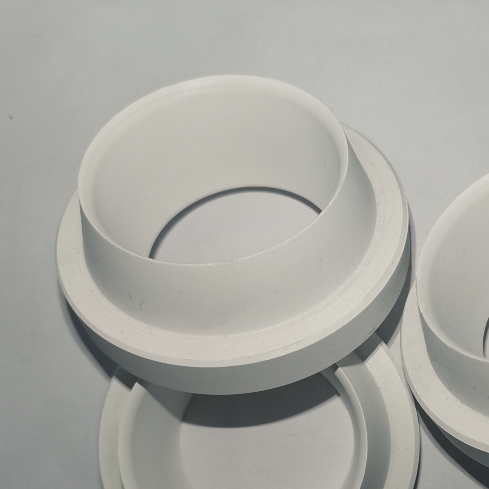

100% Original Zirconium Plates - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for 100% Original Zirconium Plates - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Portugal, Gabon, Nicaragua, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

-

Newly Arrival Ceramic Connector - Aluminum oxi...

-

Factory source Textile Ceramic Pipe - Self-lub...

-

Ordinary Discount Precision Ceramic Shaft - Al...

-

Chinese wholesale Ceramic Board - Ceramic Wate...

-

Manufacturer for Corundum Mullite Pusher Plate ...

-

Original Factory Granulator Screens - Porous c...