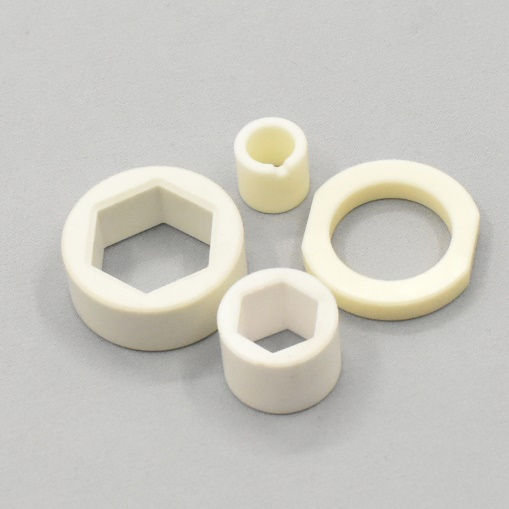

2021 New Style ceramic bearing manufacturers - Aluminum oxide Ceramic shaft / Shaft seal – SEM Detail:

Product production steps

Advantages

Excellent wear resistance, equivalent to 266 times of manganese steel.

High hardness. Far more than stainless steel in wear resistance.

Light weight, its density is 3.9g/cm3, can reduce equipment load.

The material itself is resistant to the high temperatures of 1600℃ and has good self-lubrication. There is no expansion caused by temperature difference between 100℃ and 800℃.

The material itself has the characteristics of corrosion resistance and can be used in the fields of strong acid, strong base, inorganic, organic salt, seawater, etc.

No magnetic, no dust absorption, low noise; Can be used in demagnetization equipment, precision instruments and other fields.

Application Introduction

High speed digital motor and ordinary high-speed motor.

All kinds of brushless motor pumps.

All kinds of motors with high resistance of temperature, acid, and alkali environment.

Sample case

Most cordless vacuum cleaners use a traditional brushless DC motor, which typically runs at 25,000 times /Min.

Digital motor using ceramic shaft as rotating shaft. Although small, but powerful, using digital pulse technology, generate electromagnetic force, drive magnetic force rotation, the speed of up to 125000 times /Min.

Tech specs

| Model No. | Ceramic shaft / Shaft seal |

| Main components: | Al2O3 made in Japan |

| Hardness: | ≥HV0.5N1650 |

| Bending strength: | 400Mpa |

| Compressive strength: | 3500Gpa |

| Operating temperature: | 1000℃ |

| Size: | OD 1-50mm |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for 2021 New Style ceramic bearing manufacturers - Aluminum oxide Ceramic shaft / Shaft seal – SEM, The product will supply to all over the world, such as: Georgia, Ireland, Zurich, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Factory Free sample Marble Beads - Self-lubric...

-

Hot Selling for Pigment For Plastic - Self-lub...

-

Factory Outlets Ball Valve Faucet - Ceramic Wa...

-

Manufacturing Companies for Screen Machinery -...

-

China OEM Corundum Mullite - Ceramic Water Val...

-

Super Lowest Price Glass Melting Furnace - Cer...