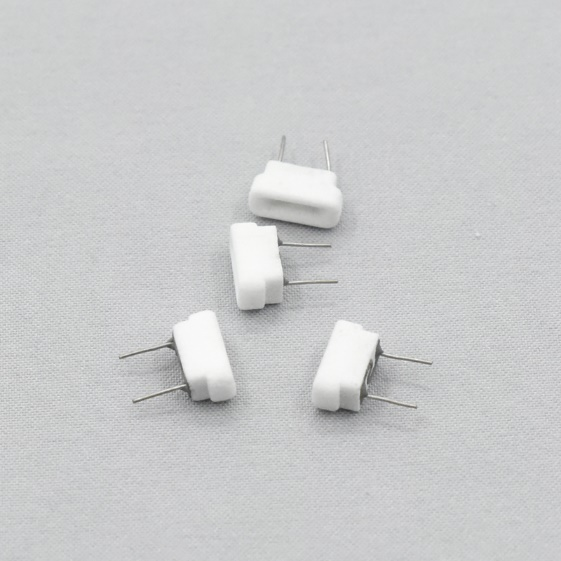

Chinese Professional E Cigarette Liquids Atomizer - Porous ceramic atomizing core – SEM Detail:

Product production steps

Advantages

The product is fired at 1050℃.No harmful ingredients remain and pass the FDA certification.

The product is vacuum sintered. No dust on the surface. No risk of inhalation into the lungs.

Ceramic strength up to 60N. Unbreakable and meet the assembly requirements.

Thick film printing circuit heats up fast and stable. Not easy to produce anxious burnt. Life is more than 350 puff.

Ceramic does not contain iron. It will not react with liquid such as smoke oil and will not change color when normal storage.

Ceramic and printed circuit are highly compatible. It can atomize more fully and taste better.

Application

Tech specs

| Model No. | Porous ceramic atomizing core |

| Aperture: | 28-32nm |

| Porosity: | >55% |

| Wicking rate: | >20mm/sec |

| Ceramic strength: | >60N |

| Temperature when heating: | 220-250℃ |

| Working life: | >350 puff(Power:6w) |

| Smoke oil consumption per puff | >6mg(Different data with different smoke bombs) |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for Chinese Professional E Cigarette Liquids Atomizer - Porous ceramic atomizing core – SEM, The product will supply to all over the world, such as: venezuela, Latvia, Libya, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

-

Hot New Products Skin Treatment Beauty Salon Eq...

-

Newly Arrival Refractory Cement Mortar - Ceram...

-

New Arrival China Single Kitchen Faucet - Cera...

-

Fixed Competitive Price Alumina Ceramic Bush -...

-

Newly Arrival Ceramic Connector - Aluminum oxi...

-

Original Factory Water Level Transducer - Capa...