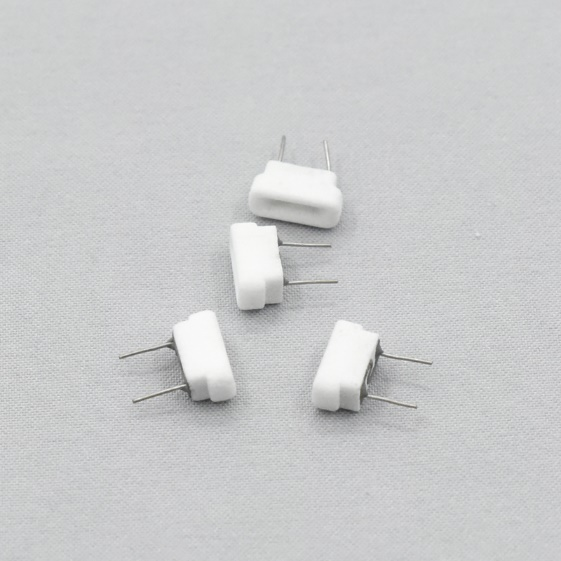

factory Outlets for Ultrasonic Nebulizer Transducer Unit - Porous ceramic atomizing core – SEM Detail:

Product production steps

Advantages

The product is fired at 1050℃.No harmful ingredients remain and pass the FDA certification.

The product is vacuum sintered. No dust on the surface. No risk of inhalation into the lungs.

Ceramic strength up to 60N. Unbreakable and meet the assembly requirements.

Thick film printing circuit heats up fast and stable. Not easy to produce anxious burnt. Life is more than 350 puff.

Ceramic does not contain iron. It will not react with liquid such as smoke oil and will not change color when normal storage.

Ceramic and printed circuit are highly compatible. It can atomize more fully and taste better.

Application

Tech specs

| Model No. | Porous ceramic atomizing core |

| Aperture: | 28-32nm |

| Porosity: | >55% |

| Wicking rate: | >20mm/sec |

| Ceramic strength: | >60N |

| Temperature when heating: | 220-250℃ |

| Working life: | >350 puff(Power:6w) |

| Smoke oil consumption per puff | >6mg(Different data with different smoke bombs) |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for factory Outlets for Ultrasonic Nebulizer Transducer Unit - Porous ceramic atomizing core – SEM, The product will supply to all over the world, such as: Iraq, Victoria, Karachi, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

-

New Arrival China Disposable E Cigarette Liquid...

-

Hot New Products Ceramic shaft seal for digital...

-

Factory made hot-sale Calcined Chamotte - Cera...

-

Professional China Control Valve - Ceramic Wat...

-

High Performance Ceramic Refractory - Ceramic ...

-

Factory selling Cylinder Head - Ceramic Water ...