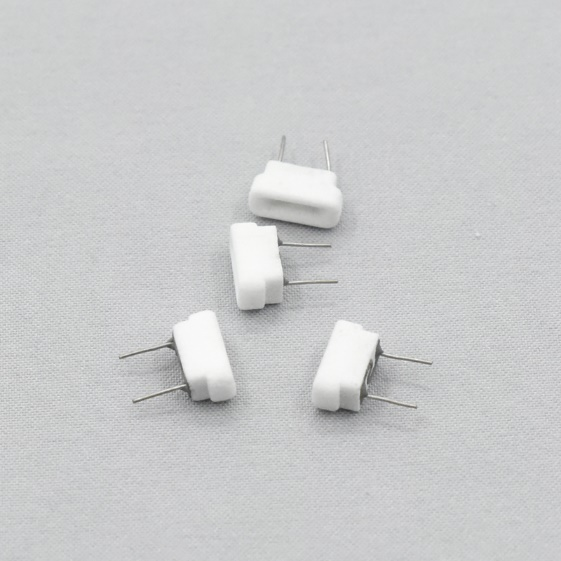

Free sample for Atomizing Spray Dryer Machine - Porous ceramic atomizing core – SEM Detail:

Product production steps

Advantages

The product is fired at 1050℃.No harmful ingredients remain and pass the FDA certification.

The product is vacuum sintered. No dust on the surface. No risk of inhalation into the lungs.

Ceramic strength up to 60N. Unbreakable and meet the assembly requirements.

Thick film printing circuit heats up fast and stable. Not easy to produce anxious burnt. Life is more than 350 puff.

Ceramic does not contain iron. It will not react with liquid such as smoke oil and will not change color when normal storage.

Ceramic and printed circuit are highly compatible. It can atomize more fully and taste better.

Application

Tech specs

| Model No. | Porous ceramic atomizing core |

| Aperture: | 28-32nm |

| Porosity: | >55% |

| Wicking rate: | >20mm/sec |

| Ceramic strength: | >60N |

| Temperature when heating: | 220-250℃ |

| Working life: | >350 puff(Power:6w) |

| Smoke oil consumption per puff | >6mg(Different data with different smoke bombs) |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Free sample for Atomizing Spray Dryer Machine - Porous ceramic atomizing core – SEM, The product will supply to all over the world, such as: Turin, Singapore, Sweden, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

New Fashion Design for Ceramic Furnace - Alumi...

-

China New Product Idling Single Sealing Plastic...

-

Personlized Products Sand Casting Aluminum Part...

-

Free sample for Atomizing Spray Dryer Machine -...

-

Hot sale Factory Ceramic Insulator Parts - Alu...

-

Good Quality Refrigeration Equipment - Ceramic...