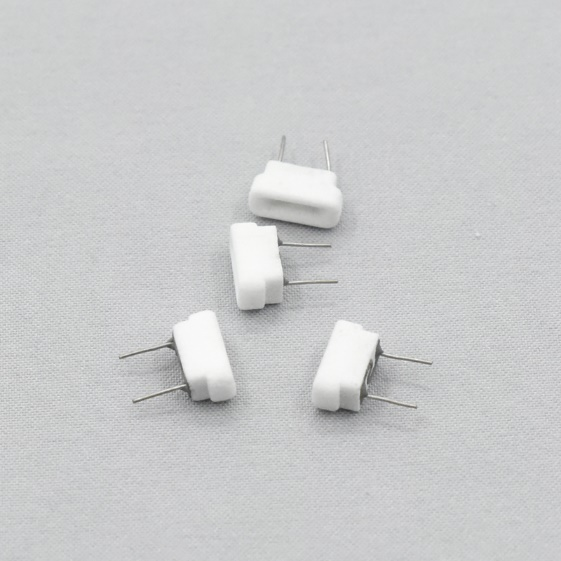

High Quality for Blower Sprayer - Porous ceramic atomizing core – SEM Detail:

Product production steps

Advantages

The product is fired at 1050℃.No harmful ingredients remain and pass the FDA certification.

The product is vacuum sintered. No dust on the surface. No risk of inhalation into the lungs.

Ceramic strength up to 60N. Unbreakable and meet the assembly requirements.

Thick film printing circuit heats up fast and stable. Not easy to produce anxious burnt. Life is more than 350 puff.

Ceramic does not contain iron. It will not react with liquid such as smoke oil and will not change color when normal storage.

Ceramic and printed circuit are highly compatible. It can atomize more fully and taste better.

Application

Tech specs

| Model No. | Porous ceramic atomizing core |

| Aperture: | 28-32nm |

| Porosity: | >55% |

| Wicking rate: | >20mm/sec |

| Ceramic strength: | >60N |

| Temperature when heating: | 220-250℃ |

| Working life: | >350 puff(Power:6w) |

| Smoke oil consumption per puff | >6mg(Different data with different smoke bombs) |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for High Quality for Blower Sprayer - Porous ceramic atomizing core – SEM, The product will supply to all over the world, such as: Austria, Naples, Lyon, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

-

China wholesale High speed digital motor cerami...

-

Hot-selling Automatic Drying Machine - Self-lu...

-

New Delivery for Heat Resistant Ceramic - Cera...

-

OEM manufacturer Roller Press Machine - Self-l...

-

OEM Factory for Briquette Machines - Self-lubr...

-

Good quality Portable Mist Spray Gun - Porous ...