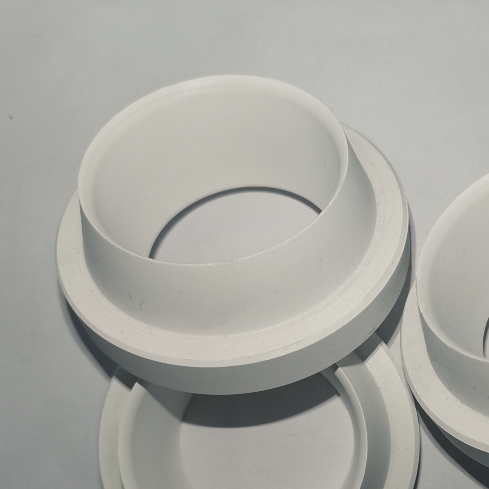

High reputation Chemical Filling - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for High reputation Chemical Filling - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Eindhoven, Uruguay, Burundi, We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

-

factory customized Self E Cigarette - Porous c...

-

Manufacturer for Disc Cartridge - Ceramic Wate...

-

18 Years Factory Inhaler Mesh Nebulizer - Poro...

-

Cheapest Price High Alumina Crucible - Ceramic...

-

factory Outlets for Pharmaceutical Machine - S...

-

Hot-selling Small Perfume Atomizer - Porous ce...