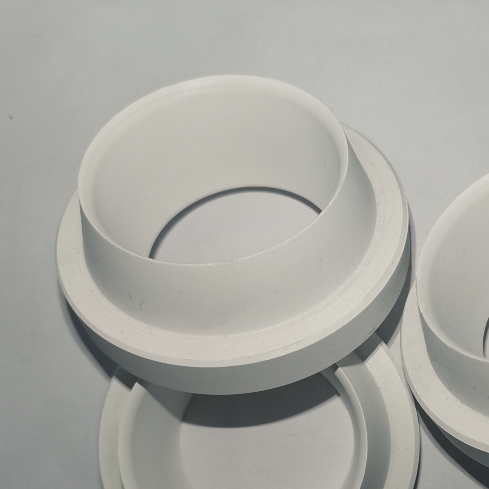

Manufacturing Companies for Special Sic Ceramic - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Manufacturing Companies for Special Sic Ceramic - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Lyon, Madagascar, Egypt, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

-

Best quality Ceramic Furnace - Ceramic aluminu...

-

China wholesale Valve Core Screw - Ceramic Wat...

-

Reasonable price for Steel Ball Bearing Wheel -...

-

Hot New Products Silicon Carbide - Self-lubric...

-

Cheapest Price Alumina Spray Prill Powder - Se...

-

Fixed Competitive Price Epoxy Powder Coating -...