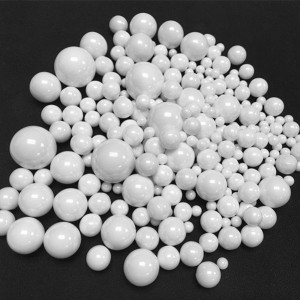

Ceramic balls and zirconia grinding beads are gaining popularity in many industries. These materials offer a wide range of advantages over traditional metal alternatives, including improved wear resistance, increased efficiency and reduced risk of contamination.

Pharmaceutical industry application

One of the latest developments in the use of zirconia grinding beads is in the pharmaceutical industry. The researchers showed that zirconia beads could be used to grind drug particles to a smaller size and achieve better drug dispersion, leading to improved bioavailability and efficacy. In addition, due to the material's high abrasion resistance and durability, zirconia beads can be used for a longer period of time, increasing efficiency and saving costs for drug manufacturers.

Food industry application

Ceramic grinding balls are often used in the food industry to produce high-quality chocolate products. The use of ceramic balls reduces the risk of contamination and produces a more consistent end product compared to metal equivalents. In addition, ceramic balls can be used to grind spices and other food additives into fine powder for more uniform taste and better texture.

Energy industry application

The use of ceramic balls is also expanding in the energy industry, especially in the coal gasification process. These environments are often harsh and abrasive, causing rapid wear on metal equipment. Ceramic balls offer increased wear resistance and durability, making them ideal for use in these challenging environments. Additionally, the use of ceramic balls can improve the quality of the final product by reducing impurities and contaminants.

Advances in manufacturing processes

Recent advances in manufacturing processes have also improved the quality and consistency in the production of ceramic and zirconia grinding balls. The computer-controlled machine produces beads with high precision and uniformity, resulting in more consistent grinding and improved results. Additionally, manufacturers are developing new formulations and production methods to create materials with better wear resistance and durability.

Environmental benefits

The use of ceramic and zirconia grinding beads also provides environmental benefits. Traditional metal abrasive media wears out quickly and releases metal and other contaminants into the environment. The ceramic material is non-toxic and does not release any harmful substances, thereby reducing the impact on the environment.

In conclusion

Ceramic and zirconia grinding balls offer a wide range of advantages over traditional metal alternatives. Advances in manufacturing processes and new applications in industries such as pharmaceuticals, food, and energy have led to increased interest and investment in these materials. In addition to their performance advantages, these materials can also provide environmental benefits by reducing the release of harmful substances into the environment.

Post time: May-11-2023