Effect of microporous ceramic atomizing core on electronic smog

1. Porosity vs. strength

The first contradiction of ceramics: the reduction of strength will cause ceramics to drop powder, at the end of the fall, the assembly is prone to fragmentation, resulting in reduced yield.

2. Pore size vs. oil conductivity

The pore size of microporous ceramics is very uneven in microstructure and does not have regular geometry. The pore size is large or small. The aperture of microporous ceramics generally refers to the interval distribution, in a continuous flow channel, the minimum aperture to the amount of oil play a decisive role, the amount of oil is proportional to the square of the aperture, the larger the aperture, the faster the oil.

3. Aperture vs. texture

In addition to affecting the oil conduction rate, aperture is another important indicator is the taste. When atomizing, if the smoke oil is a larger particle atomized, the steam flow formed is relatively coarse, and the droplets formed after condensation are larger, which has a relatively strong and exciting taste. The smaller the hole, the finer the steam flow formed by oil droplets atomization, the finer the aerosol particles formed, the better the dispersion effect, more uniform, delicate taste. Therefore, the smaller the oil guide aperture, the better.

Analysis of pain points of microporous ceramic atomizing core

The oil conduction property and strength of ceramics can not be taken into account, so large aperture is needed to obtain sufficient oil conduction capacity. Large aperture will make the aperture of the ceramic decreased; Good taste of ceramic atomizing core requires small enough aperture; Ceramic strength, oil conduction, taste requirements for aperture are exactly opposite. Ceramics in these three aspects of the performance can not give attention to both, it is contradictory. But the core of the ceramic atomization core, including the core competitiveness of e-cigarettes is the taste, which is a performance that needs to be guaranteed first. Therefore, the pore size is small enough to supply enough oil.

1. Fine pore size and high porosity:

Nano ceramic material preparation technology, control the particle size and concentration of ceramic powder, obtain fine pore structure and concentrated pore size distribution, avoid the strength loss caused by large pores. Optimize the dispersion uniformity of ceramic powder, increase the pore-making dose, and achieve high porosity

2. The light of microporous ceramics:

Change the material formula, improve the intrinsic strength of microporous ceramic materials, accurately design and control the sintering temperature, to obtain a good sintering degree, to achieve a balance between porosity and strength. Precise industrial design will achieve a balance between strength, porosity and aperture, to achieve the ideal oil conduction and taste effect.

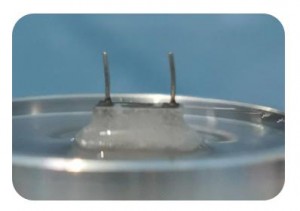

3. Another pain point of ceramic core is the evaporation of nicotine and essence in cigarette oil. It needs a stable temperature environment, and the temperature distribution is uneven. In order to pursue the ultimate taste, heating wire processing is needed for more fine processing and customization, so the current development trend of microporous ceramic atomization core is to do a customized metallization on the ceramic substrate. There are many ways to metallize ceramic surfaces, and one of the most common technologies currently used in e-cigarettes is thick film printing, similar to PCB brush solder paste. This process is not only implemented on flat surfaces, but also on 3D surfaces.

Post time: Jul-19-2022