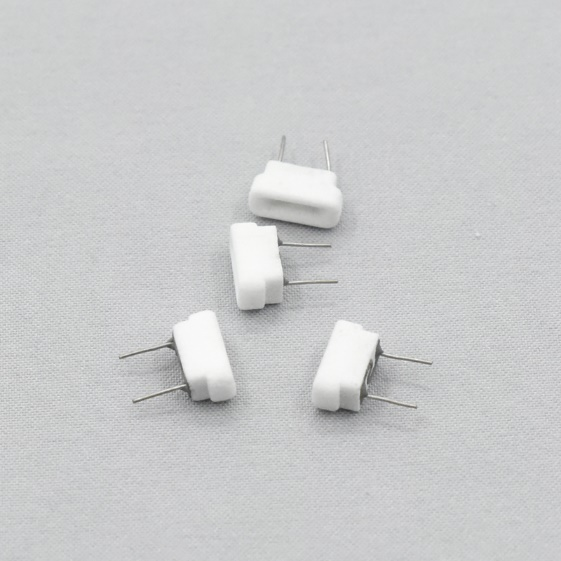

professional factory for Plastic Machine Granulator - Porous ceramic atomizing core – SEM Detail:

Product production steps

Advantages

The product is fired at 1050℃.No harmful ingredients remain and pass the FDA certification.

The product is vacuum sintered. No dust on the surface. No risk of inhalation into the lungs.

Ceramic strength up to 60N. Unbreakable and meet the assembly requirements.

Thick film printing circuit heats up fast and stable. Not easy to produce anxious burnt. Life is more than 350 puff.

Ceramic does not contain iron. It will not react with liquid such as smoke oil and will not change color when normal storage.

Ceramic and printed circuit are highly compatible. It can atomize more fully and taste better.

Application

Tech specs

| Model No. | Porous ceramic atomizing core |

| Aperture: | 28-32nm |

| Porosity: | >55% |

| Wicking rate: | >20mm/sec |

| Ceramic strength: | >60N |

| Temperature when heating: | 220-250℃ |

| Working life: | >350 puff(Power:6w) |

| Smoke oil consumption per puff | >6mg(Different data with different smoke bombs) |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for professional factory for Plastic Machine Granulator - Porous ceramic atomizing core – SEM, The product will supply to all over the world, such as: Moldova, Malaysia, Argentina, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Factory directly Refractory Andalusite Castable...

-

OEM/ODM Factory Precious Stone Jewelry Set - S...

-

Low price for Cylindrical Ball Bearing - Self-...

-

Discountable price Glass Beads Grinding - Self...

-

Lowest Price for Crucible Alumina - Ceramic Wa...

-

Factory directly Alumina Grinding Wheel - Self...