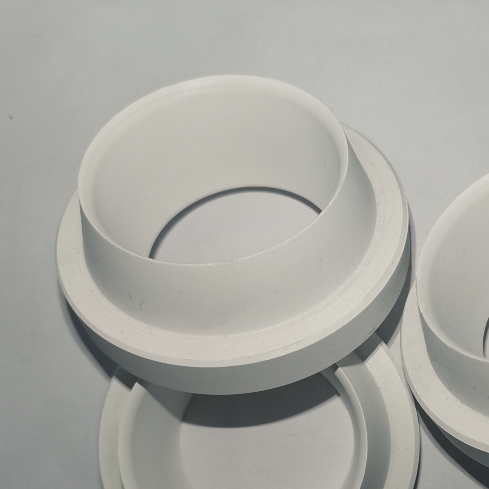

professional factory for Refractory Ceramic Ring - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for professional factory for Refractory Ceramic Ring - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Vietnam, Uganda, Canberra, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

-

Big Discount Plastic Granulator - Porous ceram...

-

Chinese wholesale Motor ceramic shaft seal - A...

-

China Cheap price Water Pressure Transducer - ...

-

Online Exporter Cartridge Housing - Ceramic Wa...

-

Factory source Fuel Level Sensor – Capaci...

-

100% Original Factory Electronic Appliances - ...