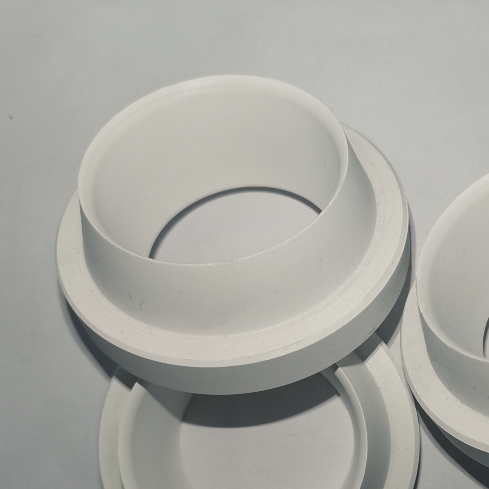

Wholesale Ceramic Decors - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for Wholesale Ceramic Decors - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Denver, Saudi Arabia, Amsterdam, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Special Price for Cordierite Parts - Ceramic W...

-

Top Suppliers Fire Fighting Level Sensor - Cap...

-

2021 High quality High Alumina Grinding Ball -...

-

Online Exporter Corundum Crucible - Ceramic Wa...

-

Top Quality Firefighting Equipment - Porous ce...

-

Factory wholesale Industrial Ceramic - Self-lu...